Interior design trends come and go, but some classic elements stand the test of time. We’ve all come across interesting attempts to recontextualize different parts of a home with things like velvet pile carpets and popcorn ceilings; fun trends that can end up looking a little dated after a few years. However, there is one classic design trend that continues to shine brightly.

Tin ceilings have stood as a hallmark of luxury, class and elegance for almost 150 years, providing a wide range of practical and aesthetic benefits to owners of historic and modern homes. But have you ever wondered where this trend came from? Or how tin ceiling tiles have changed over the years? Learn all about the interesting history of tin ceilings below.

The origins of tin ceilings in the US

Tin ceiling tiles were first introduced to the American market in the mid-to-late 1800s, being sold as a more affordable alternative to the ornate plasterwork ceilings that were popular in Europe at the time. New immigrants wanted to emulate the classy aesthetics of the high-end properties they encountered back home, but plaster proved expensive and hard to work with.

Around 1880, American manufacturers discovered a repeatable and affordable way to turn thin, rolled-tin plates into durable and versatile panels. These panels were malleable enough for intricate designs to be stamped into their surface, yet durable enough to withstand typical wear and tear. The result? An easily-customizable, striking and affordable finishing material.

Tin ceilings boomed in popularity across America, becoming commonplace in all manner of high-end homes, churches and private businesses, but demand for spare metal during world war two caused production to halt. Today, tin ceilings are enjoying a resurgence in popularity, with modern manufacturing techniques making tin panels more accessible than ever before.

Why tin ceiling tiles became so popular

The original draw to tin ceilings centered on an aesthetic similarity to plasterwork, but as tin ceilings became more popular, property owners began to discover many additional benefits.

- Aesthetic appeal: Tin ceilings add a whole new dimension to grand buildings, with painted tiles emulating ornate plasterwork and natural tiles making spaces feel larger.

- Fire resistance: The ability for tin tiles to withstand fire was a big selling point when most homes were lit and heated by open flames, adding to tin tiles’ unique versatility.

- Durability: Tin tiles are hard-wearing, so much so that many older buildings still have original tiles from the 1800s, though some may be in need of a little restoration work (read more here about our Replica Tin Ceiling Tiles service).

- Ease-of-use: Tin tiles are very lightweight, making them easy to transport and install. This benefit still stands today, enabling homeowners to craft unique DIY installations.

- Customization: Classic rolled-tin, and even modern tin-plated steel, can be stamped with relative ease to create a multitude of unique designs to meet most design styles.

Tin ceilings today

Tin ceilings have enjoyed a surge in popularity in recent years, with modern tin and faux-tin ceiling tiles now more affordable, versatile and customizable than ever before. A few things have changed, mostly concerning how tiles are made, panel sizes and installation methods, with all of these developments helping tin ceilings reach a wider variety of property owners.

Manufacturing

Rather than being made from thin rolled-tin, modern tiles are made from 30-gauge tin-plated powder coated steel. This makes for a more durable product that retains the same aesthetic charm, allowing for longer-lasting installations. Faux-tin tiles made from PVC or styrofoam are also a popular modern choice, providing a similar visual appeal but usually placing these ceiling tiles at a cheaper price-point.

Panel sizes

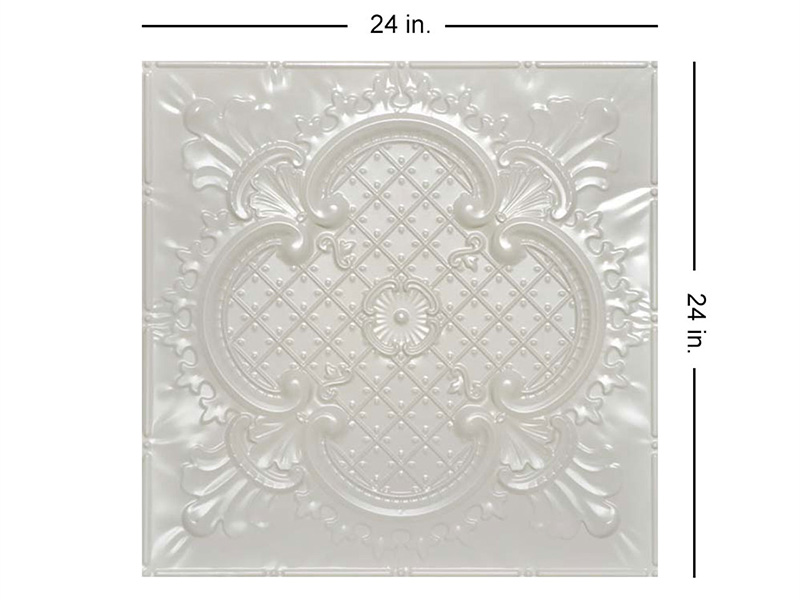

Up until around 1950, all manufactured tin tiles measured 2ft x 8ft, and were designed to be mounted directly onto existing surfaces. After the invention of the ceiling grid system in 1961, companies started to make drop-in tiles in a wider range of sizes. 2ft x 2ft and 2ft x 4ft tiles became more popular as larger 2ft x 8ft tiles fell out of favor due to being harder to install.

To help homeowners plan perfect installations, modern tin ceiling tiles come in standardized sizes. The most common of these sizes is 24” x 24” (2ft x 2ft), but 24” x 48” (2ft x 4ft) and even 24” x 96” (2ft x 8ft) are routinely produced by manufacturers to suit all kinds of projects.

Installation types

Modern tin ceilings can be installed in a few ways, with the two most common being nail-up and drop-in installations. Nail-up tin tiles can be affixed directly to a plywood base attached to a room’s existing ceiling. Drop-in tin ceiling tiles can be hung from a metal grid suspended below a structural roof, lowering the old ceiling in order to hide unsightly wires and ductwork.

Modern tin ceiling considerations

Now that tin tiles are accessible to all kinds of homeowners, it’s incredibly easy to develop your own custom tin ceiling projects. However, to help ensure your installation meets your needs in terms of design and practicality, it’s worth thinking about the below considerations.

Finishes

Modern tin ceiling tiles come in a variety of finishes, including painted, clear polyurethane and sheer metal finishes. While it’s common for all metal tiles to be referred to as tin ceiling tiles, you can also find copper, brass, aluminum and even rustic steel tiles to suit your style.

Aluminum tiles have grown popular in recent years as they’re lightweight, rust-resistant and easy to work with, while copper ceiling tiles are a common choice for upscale projects. No matter your aesthetic, it’s easier than ever to find a fitting type of tile that suits your budget.

Costs

While tin ceiling tiles are much more affordable nowadays, costs can rise depending on the finish and design complexity of different products. Basic, unfinished 2 x 2 tiles are about $11 per unit, while powder-coated versions cost around $18. Hand-painted tiles of the same size are about $50 per unit, while high-end products like aged-copper tiles can cost $129 per tile.

Extra elements

To create a truly awe-inspiring tin ceiling, it’s worth exploring extra finishing elements to help accentuate the intricacies of your chosen designs. Tin cornices and faux-tin cornices, grid covers and metal crown molding trims (we also have a range of non-metal based crown moldings) can all be used to add extra depth and character to your chosen panels.

Wrapping up

From their beginnings as an innovative alternative to European plasterwork, to their current applications across the ceilings, walls and tin backsplashes of modern homes and businesses, tin ceiling tiles and tin ceilings themselves have become a staple of American interior design.

Creating your own bespoke tin ceiling is a great way to add a touch of historical elegance to any space. Whether you have a specific project in mind, or you’ve just begun to consider the benefits of creating a new tin ceiling, Decorative Ceiling Tiles has all the materials you need.